STELLAR SHIPS HAVE A STELLAR COATING

QUICK STATS

| Vessel Owner | Polaris Shipping |

| Vessel Name | Stellar Young, Stellar Way and Stellar Venture |

| Location | Philippines, Singapore, China based yards |

| Vessels | VLOCs |

| Type of Application | Drydocking |

| Coating System | FASTAR I, FASTAR XI, NEOGUARD 100 GF |

| Application Vessel Area | Flat Bottom, Vertical Bottom, Boottop |

| Date of Delivery | 2022 – 2023 |

THE CASE STORY

Since its official market entry in January 2021, we have applied the new nano-type FASTAR® coating to almost 200 vessels. The most recent applications include a trio of Polaris Shipping owned VLOCs, Stellar Young, Stellar Way and Stellar Venture.

Although FASTAR has yet to be fully benchmarked given the coating’s recent introduction, performance indicators suggest the coating could even succeed the popular LF-Sea® range as the maritime industry’s antifouling of choice.

The nano-based antifouling technology is certainly finding favour with shipyards, with the China-, Singapore- and Philippines-based yards that drydocked the Polaris vessels earlier this year all finding FASTAR reduced curing and application time considerably.

While Polaris Shipping is no stranger to the high-performance attributes of our antifouling technologies, having first specified the LF-Sea in 2010, and subsequently A-LF-Sea® the shipowner, was keen to try the FASTAR system to minimise fouling when ships were idle.

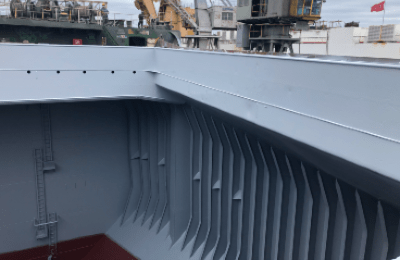

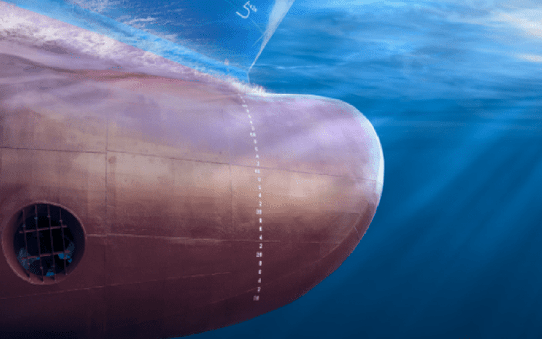

To this end, we recommended a FASTAR I application to the vessels’ boottops and flat bottom and the hydrogel-containing FASTAR XI to the vertical sides to reduce fuel consumption by as much as 8%. To reduce the risk of damage to hull coatings when berthing alongside we applied the glass flake NEOGAURD coating to add additional impact protection.

It is often thought that expenditure and environment protection are inversely proportional. But FASTAR has been found to reduce costs and protect the environment at the same time. This remarkable antifouling technology shortens the time in drydock for coating applications, reducing costs and off-hire time, allowing ships to return to service quickly and the cost of repairing the shipyard will be reduced. And when they back in service, they find fuel consumption has reduced.

Like Polaris Shipping, we are a company that strives to reduce the impact of shipping on the marine environment. The development of FASTAR is very much in line with the needs of our customers and their energy efficiency requirements.