A-LF-SEA

A-LF-SEA

Ultra fuel-saving SPC antifouling

Applied to over 5,000 ships, lowering global fuel consumption

A-LF-SEA

Ultra fuel-saving SPC antifouling

Applied to over 5,000 ships, lowering global fuel consumption

DOWNLOAD DOCUMENTATION

OVERVIEW

The World's Most Trusted Ultra-Low-Friction SPC coating system

Used on some of the world’s most prestigious ships, A-LF-Sea is the world’s most advanced and trusted ultra-low-friction coating system. A-LF-Sea is an advanced version of LF-Sea delivering further propulsion benefits.

A-LF-Sea is a biomimetic super-low-friction antifouling that works using a patented water trapping function to lower the hydrodynamic footprint of the hull. Stable and long term antifouling is guaranteed by the use of a self-smoothing copper-silyl-acrylate copolymer.

Key Features

Long term and stable self-polishing

HYDROGEL WATER TRAPPING TECHNOLOGY

Smoother hull and super low friction

Applicable using standard practice and equipment

FEATURES

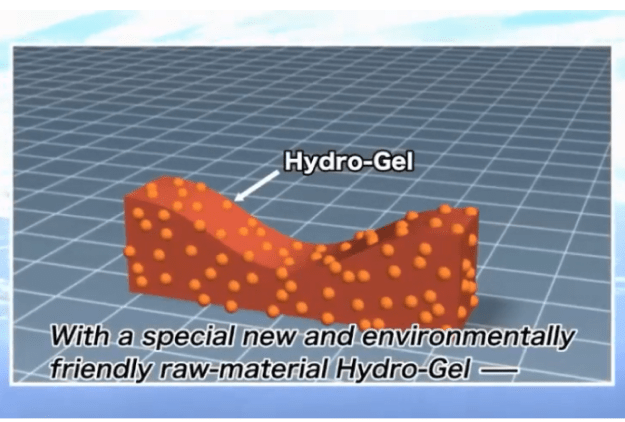

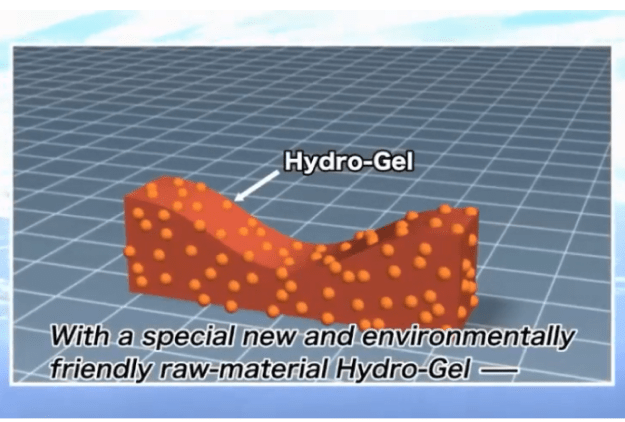

Water trapping technology

- A-LF-Sea was designed to produce an enhanced water trapped layer by the use of a new improved blend of Hydrogel – HydroSmoothXT™, Hydrogel Water Trapping Technology

- See the concept of water trapping and how it works in an SPC shown in this video.

- By having a microscopic layer of water trapped on the hull’s surface, the water flow around and against the hull is smoothened.

Rheology Control

Rheological Control is a special technology concerning flow of coatings.

Nippon Paint Marine’s teams developed a special version of our epoxy anticorrosive and antiabrasive coating that forms a smoother film than normal epoxies.

Slowing down the initial curing mechanism by special chemistry delivers significantly smoother film. This smoother film gives a lower initial surface roughness for A-LF-Sea to perform to its fullest potential.

Rheology Control

Rheological Control is a special technology concerning flow of coatings.

Nippon Paint Marine’s teams developed a special version of our epoxy anticorrosive and antiabrasive coating that forms a smoother film than normal epoxies.

Slowing down the initial curing mechanism by special chemistry delivers significantly smoother film. This smoother film gives a lower initial surface roughness for A-LF-Sea to perform to its fullest potential.

Reduction of frictional resistance

- The combined effect of Nippon Paint Marine’s enhanced hydro-gel technology, added to Nippon Paint Marine’s Rheology Control technology, creates a 15% reduction in frictional resistance compared to other antifouling paints.

- This 15% reduction in frictional resistance of the flat plate leads to an approximate 10% reduction in fuel consumption and CO2 emissions helping ship owners to positively contribute to the global environment.

Reduction of frictional resistance

- The combined effect of Nippon’s enhanced hydro-gel technology added to the lower roughness from Nippon’s Rheology Control technology leads to a 15% reduction of frictional resistance compared to other antifouling paints.

- This 15% reduction in frictional resistance of the flat plate leads to an approximate 10% reduction in fuel consumption and CO2 emissions helping ship owners and positively contributing to the global environment.

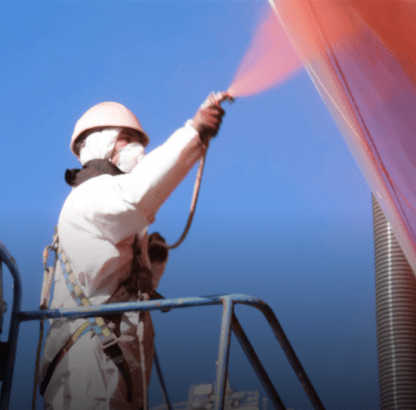

APPLICATION

A-LF-Sea is easy to apply.

A-LF-Sea is easy to apply. A-LF-Sea uses conventional painting equipment and needs no special or expensive masking.

Standard painting procedures can be used. A-LF-Sea can be applied onto most existing SPC coatings in acceptable condition.

- Application guide

M&R - Full blasting

- Newbuilding

*Please contact your local Nippon Paint Marine representatives for more details.

CERTIFICATION

A-LF-Sea series complies with IMO-AFS2001 as tin-free anti-fouling system. Certification from Classification Societies is available.

- JPMA (Japan Paint Manufactures Association)

- DNV-GL

- Lloyd’s Register

- Korean Register

PRODUCT RANGE

Ultra fuel-saving SPC antifouling

• Zinc Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Ultra Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Ultra Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Ultra fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Ultra fuel-saving SPC antifouling

• Zinc Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Ultra Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Ultra Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Ultra fuel-saving SPC antifouling

• Zinc Acrylate Copolymer

• Water Trapping Technology

• Easy Application