Underwater Hull

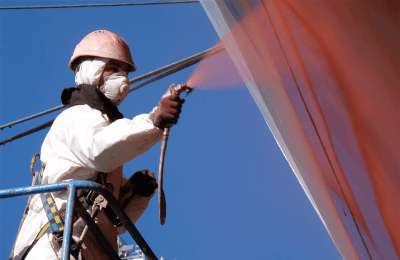

UNDERWATER HULL COATINGS

The structural body, or shell, of the ship is responsible for buoyancy and is key to operational efficiency.

UNDERWATER HULL COATINGS

The structural body, or shell, of the ship is responsible for buoyancy and is key to operational efficiency.

OVERVIEW

Our unique hull coatings prevent biofouling, reduce fuel consumption, and increase overall operational efficiency.

WHY CHOOSE OUR COATINGS?

Environment

Nippon Paint Marine’s coatings are all designed with environmental benefit in mind.

Biocide free, low friction coatings save fuel, reduces emissions, and minimise time in dock.

Worldwide supply

Available worldwide in all major dry dock locations. We’ll be there whenever you need us for products and technical services.

Whenever and wherever

Hot, cold, dry, or humid – dry dock locations have all kinds of climate challenges. Our coatings are designed to be applied whenever or wherever you dry dock.

When we help you choose an underwater hull coating, we assist in helping you specify a coating that not only delivers long-term performance and low maintenance, but can also be applied quickly to reduce your application costs and time in dock.

PRODUCT RANGE

Anti-corrosive Coating for Outer Hull

• Multi-Purpose Primers

Glass Flake Epoxy Coating

Multipurpose Primer (Aluminium)

High Performance Glass Flake Epoxy Coating

Nanodomain Structured Self-polishing Antifouling incorporating hydrogel for extra low-friction performance

• NANO-Technology

• Water Trapping Technology

Ultra Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application