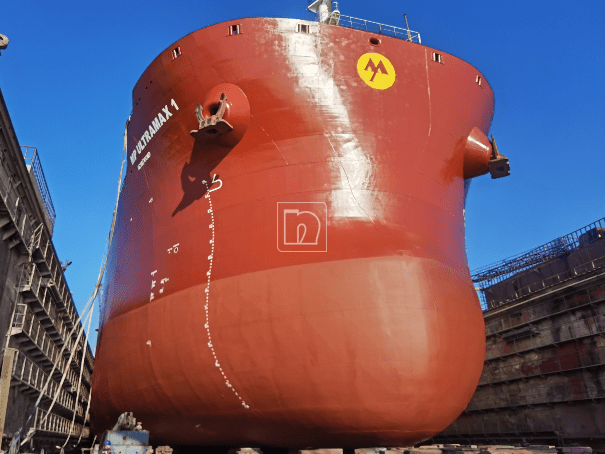

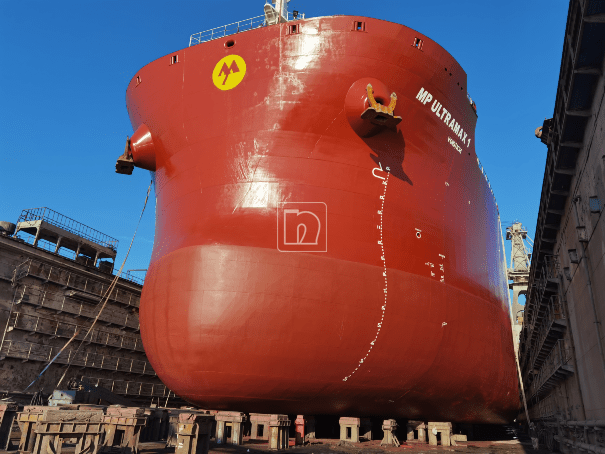

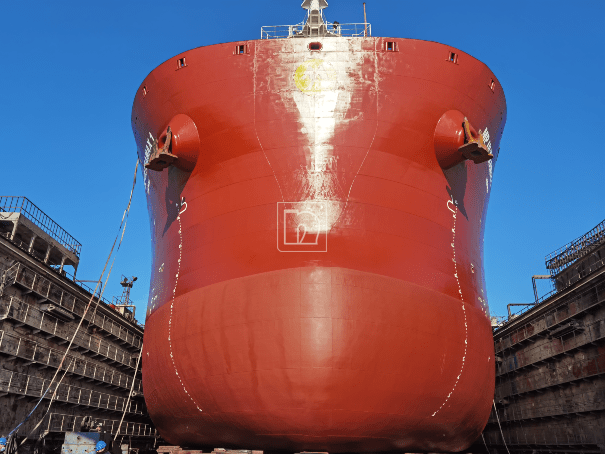

M.V. MP ULTRAMAX 1

QUICK STATS

| Vessel Owner | M. Pallonji Logistics Singapore Pte., Ltd. |

| Location | Ruitai Nantong Shipyard, China |

| Vessel Type and Tonnage of Vessel (DWT/GT) | Bulk Carrier / 63,340 DWT |

| Type of Application | Drydocking |

| Products | FASTAR I, FASTAR XI |

| Applied Vessel Area | Flat Bottom, Vertical Bottom |

| Date of Application | December 2021 |

HEAR FROM OUR CUSTOMERS

Crystal Cruises are very happy with the performance of Nippon Paint Marine’s LF-Sea range. It lowered our hull friction and reduced the maintenance in dock.”

Simon yeo

Crystal Cruises

THE CHALLENGES

Our customer M Pallonji group used LF-Sea in 2021 on their vessels, Tanker 1 and Tanker 2. M Pallonji group was keen to apply fuel saving antifouling. Nippon Paint Marine India team explained the benefit of using FASTAR the first nanodomain structured antifouling in marine industry to the customer. We added that we have been leading the way in the market with innovative antifouling technologies and how our technologies have been developed with long history: world’s first TBT free antifouling in 1990, world’s first 4% fuel saving antifouling (LF-Sea) in 2007 to 2008, 10% fuel saving antifouling (A-LF-Sea) and world’s first biocide free antifouling (AQUATERRAS). The key features of FASTAR such as low friction, high efficiency, and fuel saving were what M Pallongji group was looking for.

THE RESULTS

In 2022, FASTAR system (FASTAR I on flat bottom and FASTAR XI on vertical bottom) has been successfully applied to ULTRAMAX 1. Customer could see overcoating interval and lesser flooding time of FASTAR system compared to LF-Sea.