NOA 10

Self-Indicating Epoxy Coating for use in Newbuilding and Drydock

NOA 10

Self-Indicating Epoxy Coating for use in Newbuilding and Drydock

DOWNLOAD DOCUMENTATION

OVERVIEW

The NOA 10 range uses NOA's unique SI (Self-Indication) technology which enables the painter to visually judge if the appropriate film thickness (wet/dry) has been achieved. There are two product ranges in NOA 10, the NOA 10M which is a self-indicating epoxy coating for use in dry-dock and the NOA 10F which is an anti-corrosive and primer for newbuilding use.

NOA 10M

NOA 10M is designed specifically with repairs in mind. NOA 10M provides a unique solution to issues seen in the every busy and frenetic world of ships in dry dock. NOA 10M’s high build and self-indication functions enable the owner to apply one coat knowing that this will be applied at the correct thickness.

NOA 10F

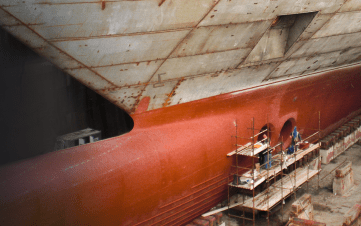

NOA 10F is a dedicated and multi-purpose anti-corrosive and anti-abrasive primer for newbuilding use. NOA10F provides both owners and shipbuilders with a multitude of benefits and ensures that the newbuilding is applied with the correct and agreed specification.

NOA’s unique SI (Self-indication) function clearly shows both the applicator and the owner’s and yard’s inspectors where any low dry film thickness may be.

Key Features

Heavy duty. Good adhesion. Proven protection.

Specified DFT secured. Coating quality & protection performance improved.

Construction period shortened. Interval free system. Easy stocktaking.

FEATURES

NOA 10F For newbuilding and refurbishment

A dedicated, multi-purpose anti-corrosive & antiabrasive primer for newbuilding use.

NOA10F provides both owners & shipbuilders with a multitude of benefits and ensures that the newbuilding is applied with the correct and agreed specification. NOA’s unique SI (Self-indication) function clearly shows both the applicator and the owner’s & yard’s inspectors where any low dry film thickness may be.

Owner’s Benefit

- Long term protection

- Strong & tough epoxy coating

- Ability to overcoat

Builder’s Benefit

- Reduction of DFT measurement

- Reduction of Touch-up & repear

- Assured quality control

- Fewer application procedures /coats

NOA’s SI function provided assurance and reliable protection during the yard’s building process. Management of the coatings and the assurance of dry film thickness is confirmed.

Superior adhesion to various final cosmetic coats. A single coat of anticorrosive possible due to NOA’s performance and SI function.

Owners benefit greatly from reduced maintenance coats after delivery. It comes from NOA’s reliability and quality and the assured thicknesses. NOA’s ability to assist the yard and the Owners’ coating inspectors to ensure that the specification has been met saving time and improving production.

NOA 10M For Maintenance and Repairs

A unique solution to issues seen in the ever busy and frenetic world of ships in drydock.

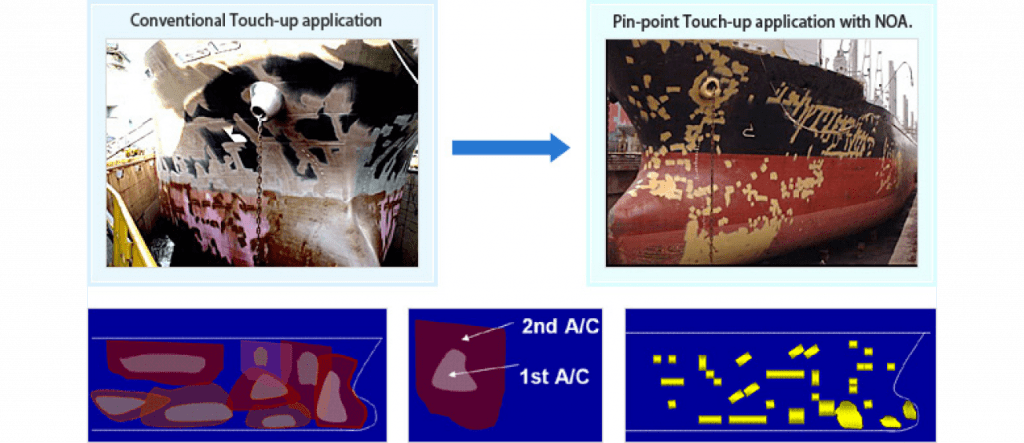

Unique product which colour shows the film thickness. Reduction of overlap areas. With conventional anticorrosive touch ups, as more coats are applied – the width of the touch up has to expand. NOA10M reduces this greatly allowing the owner to use more of the existing antifouling paint.

Increased accuracy of touch up and anticorrosive application in the drydock will reduce maintenance at the next docking.

This is a pin-point touch-up application with NOA10M. The unique SI function of NOA10M makes it possible to apply the appropriate A/C touch-up for spot-blasted areas with specified DFT.

This is a pin-point touch-up application with NOA10M. The unique SI function of NOA10M gives a high quality A/C coating film even in a tight dry-dock schedule.

NOA10 is suitable to be applied with SPC antifoulings. No tie coat needed.