INNOVATION

INNOVATING THE FUTURE OF MARINE COATINGS

INNOVATION

INNOVATING THE FUTURE OF MARINE COATINGS

A HISTORY OF FIRSTS

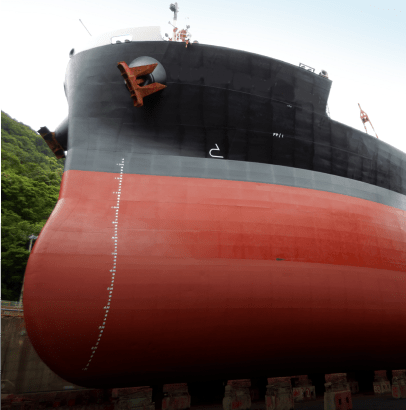

From developing ECOLOFLEX, the first tin-free coating in the world in 1990, to the launch of NOA, an advanced anticorrosive self-indicating epoxy anticorrosive system range in 1997; to developing our ultra-low friction antifouling paint A-LF-Sea in 2013, Nippon Paint Marine has been at the forefront of technical innovation for decades.

And now, AQUATERRAS, the world’s first completely biocide-free and proven self-polishing underwater foul-resistant paint that provides up to 14.7% fuel saving compared to market average speed loss, and FASTAR, the shipping industry’s first nanodomain structured hydrolysis antifouling coating that provides up to 14.1% fuel saving compared to market average speed loss, Nippon Paint Marine is innovating the future of marine coatings.

Up to 14.7% fuel savings compared to market average speed loss.

Reduction in fuel consumption measured on ships applied with AQUATERRAS

R&D LAB

INNOVATIONS

OVER

3000

FORMULATIONS

We have developed in-house technology that can rapidly test new materials by utilising big data and AI.

FROM THE LAB TO THE YARD

our innovations

INNOVATION IS IN OUR DNA

Our people are trusted to give honest, reliable and expert advice; guiding you on the best solutions to improve operations, increase efficiencies, reduce costs and emissions and protect your most valuable assets under the harshest of conditions.

However, we’re not just committed to being at the forefront of technical innovation. We thrive on building long term partnerships. Our team is by your side throughout the lifetime of your ship providing technical, training and ongoing monitoring services to ensure maximum efficiency.

SOLUTIONS

In total, our antifouling and other systems have been applied to more than 40,000 vessels from tankers and container ships to cruise liners and yachts.

Learn more about our solutions

SEE SOLUTIONS ➔

R&D CENTRE LOCATIONS

We operate at the forefront of technical innovation, investing in state-of-the art research and development (R&D) facilities focused on delivering progressive solutions that break new ground. Our R&D facilities support you in meeting your challenges and accelerate the path to decarbonisation and wider sustainability.

Nippon Paint Marine has three R&D facilities in Japan, in Osaka and Tokyo as well as our state-of-the-art, 5,978 sqm Marine Seafront Research Centre in Okayama, the first of its kind for marine coatings makers.

-

2-1-2 Oyodo Kita, Kita-ku, Osaka

531-8511 Japan - +81(6) 6455-9491

OSAKA

Keystone of Nippon Paint Group's R&D

-

4-chōme−1−15 Minamishinagawa, Shinagawa City, Tokyo

140-0004 Japan - +81(3) 3740-1140

TOKYO

Head office in metropolitan area

-

2032, Gokan, Tamano, Okayama

706-0315, Japan - +81(863) 41-1526

OKAYAMA

Marine Seafront Research Center

The development of new antifouling coatings demands in-depth research on the ecology, physiology and attachment mechanisms of marine life. We pride ourselves on our detailed insight and evaluation of each species’ adhesion and growth nuances, which has enabled us to develop and deploy reverse engineering capabilities to deliver preventative solutions.

Fundamental Research and Development

Development of underwater antifouling paint requires deep research on both the ecology and attachment mechanisms of marine life. Our research centre, the first of its kind in the world for marine coatings’ suppliers has enriched basic research, including the study of marine growth, its attachment and consequently its prevention. As a result, research by Nippon Paint Marine was able to develop the world’s first tin-free antifouling paint in 1991, thereby providing environmentally friendly, high-quality, high-performance underwater products to the world and to tens of thousands of ships. This technology helped shipping to reduce fouling and lower marine environmental pollution. We also created and launched the world’s first low-friction antifouling and the world’s only biocide-free SPC coating from our work here.

Research on Adherence / Adherence Prevention of Marine Life

We breed marine growth and research its physiology, ecology and adherence mechanism. Also, we multifacetedly and comprehensively undertake the elucidation of marine growth’s adherence and its prevention, such as through studying adherence prevention by reversely using the adherence mechanism.

Resin / Paint Design

Research to maximise the effectiveness of new antifouling and their effects, Nippon Paint Marine carries out basic and ground-breaking research into new coating types.

Evaluation

Long-Term Evaluation Research. We conduct extensive testing of new formulations using rafts and dynamic tests at five test stations in Japan and others globally. We carefully study antifouling properties as well as measuring a myriad of other physical coating properties. We extrapolate these results and can accurately model how the new coatings would work in service on ships.