Fuel Saving

Fuel-Saving Antifouling Solutions

Reducing Fuel Consumption and Vessel Emissions

Fuel-Saving Antifouling Solutions

Reducing Fuel Consumption and Vessel Emissions

OVERVIEW

A leader in fuel-saving technologies.

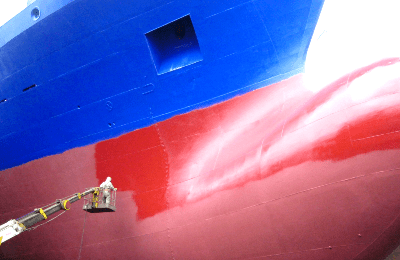

A specialist team from Nippon Paint Marine’s R&D programme, which included experts in polymer science, biochemistry, fluid dynamics and marine science, studied the natural characteristics of marine life to inform the development of the HydroSmoothXT™ technology that would be used in their industry leading coatings. This approach to technology development, of imitating nature, is known as biomimetics. The performance of Nippon Paint Marine’s antifouling coatings range – which include LF-Sea, A-LF-Sea, and FASTAR – has been enhanced using this technology, and has been applied to more than 5,000 vessels.

By replicating the natural surficial film found on the skin of marine life, Nippon Paint Marine researchers have been able to develop coatings that minimise friction, reduce fuel consumption, and lower vessel emissions.

FEATURES

Antifouling

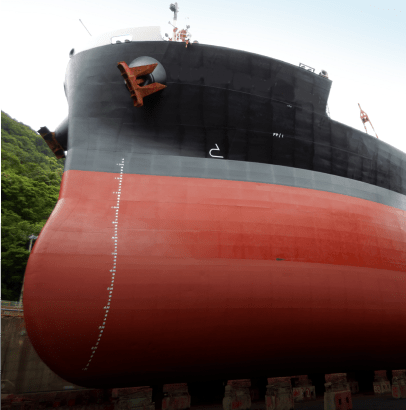

Precise and reliable self-polishing antifouling that works in all marine ecosystems – effective for up to 90 months.

HydroSmoothXTTM technology

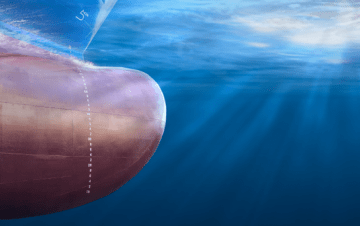

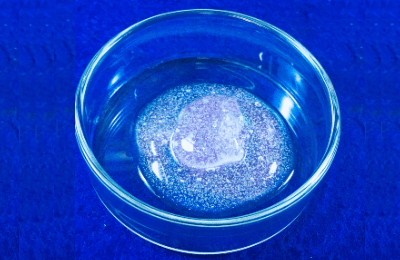

In 2006, Nippon Paint Marine patented HydroSmoothXTTM, the world’s first hydrogel-based antifouling technology. The water trapping technology smooths water flow around the hull, reducing friction, drag, fuel consumption, and emissions.

Smooth surface

Having a low surface roughness is vital for low-friction performance. All Nippon Paint Marine’s underwater antifoulings are SPCs (self-polishing copolymers) ensuring that initial low hull roughness is maintained over time.

Our groundbreaking technology helps to lower the ship’s environmental impact through reducing frictional resistance, lowering fuel consumption and reducing emissions.

PRODUCT RANGE

World’s First Biocide-Free SPC

• Biocide-free SPC Technologies

• New Hydrolysis Polymer Structure

• Low Friction Coating Technologies

Nanodomain Structured Self-polishing Antifouling incorporating hydrogel for extra low-friction performance

• NANO-Technology

• Water Trapping Technology

Ultra Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

Ultra Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application

World’s First Biocide-Free SPC

• Biocide-free SPC Technologies

• New Hydrolysis Polymer Structure

• Low Friction Coating Technologies

Nanodomain Structured Self-polishing Antifouling incorporating hydrogel for extra low-friction performance

• NANO-Technology

• Water Trapping Technology

World’s First Biocide-Free SPC

• Biocide-free SPC Technologies

• New Hydrolysis Polymer Structure

• Low Friction Coating Technologies

Ultra Fuel-saving SPC antifouling

• Copper Silyl Acrylate Copolymer

• Water Trapping Technology

• Easy Application